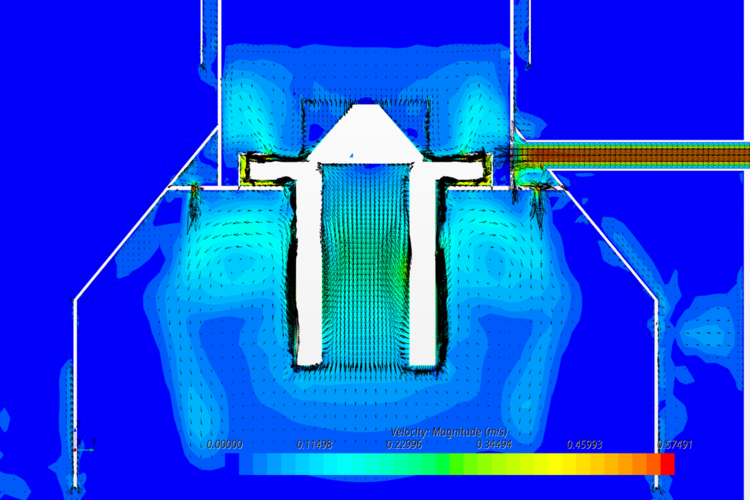

Both gravity separation processes and the inner workings of decanters themselves are often poorly understood and based on empirical relationships and previous company experience. In order to gain an in-depth understanding of the inner workings of decanters, a CFD simulation can be performed.

The general purpose of this project is to see what happens inside the decanter of the pilot plant in its ordinary operation by means of a simulation using CFD software.

The project arises from a proposal of the company STS in collaboration with the Department of Energy Engineering of the School of Engineering of Bilbao (EIB), with previous experience in the use of CFD software.

Thus, within the framework of this project, a simulation will be carried out using computational fluid mechanics software to study the internal operation of the Accentrifloc decanter for sludge recirculation of the CATABB pilot plant.

The approach of this project is done in 2 fronts:

- Stages in which new processes occurring simultaneously inside the equipment (flocculation, sedimentation, turbulence, turbine rotation, chemical processes, multiphase mixtures, liquid-gas interface…) will be successively added.

- In a first stage, we will try to simulate the internal operation of the decanter considering a single phase, taking into account only the water and adding the effect of the turbine rotation.

The study of new stages will depend on the results obtained in previous stages, and some of them may constitute a starting point for future lines of research.

On the other hand, different 3D models will be used, in which the degree of detail of the decanter geometries will be increased in order to check the suitability of the generated model and to have a first approximation of the flow field inside the equipment.